|

|

|

|

| View previous topic :: View next topic |

| Author |

Message |

wendortb

Joined: 15 Nov 2006

Posts: 107

Location: Martinsville, IN

|

Link Posted: Thu Jan 03, 2008 8:55 pm Post subject: Furnace blower too loud Link Posted: Thu Jan 03, 2008 8:55 pm Post subject: Furnace blower too loud |

|

|

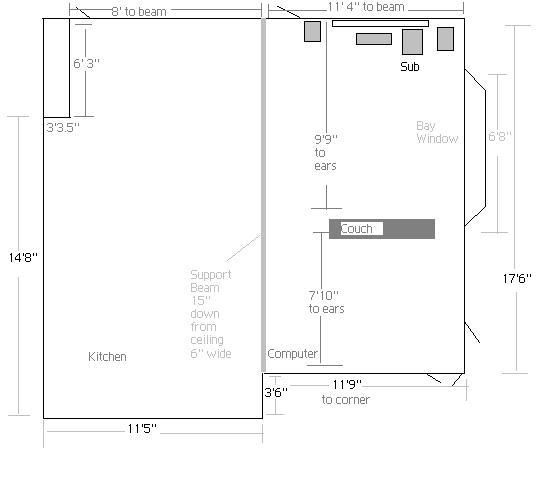

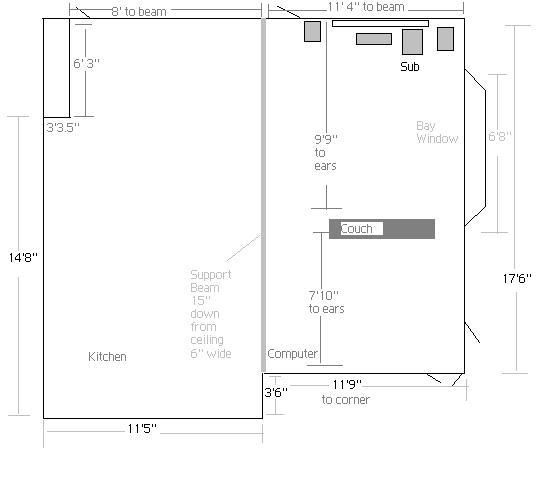

I have a house that has a multipurpose room that contains my home theater. I have been living with a noisy forced air heating and air conditioning system. I am hoping someone on here has some insight into ways to quite this down. I am working on turning my theater 90 degrees which will put me alot closer to the furnace. In the picture, I will be sitting under the beam, my second row will be even closer to the furnace.

The top left corner of the picture shows where my hvac system and water heater are located. This is a closet with 2 bifold closet doors that have slats in them on the 6'3" section.

Right now, at my seating position on the couch, the furnace is about 58db. Getting kind of close to the furnace it is 70db. Really it is the cold air return that is giving me most of the noise. The front of the furnace is bearable, but just around the corner, (the 3' 3.5" section of the closet) is extremly loud. At the bottom of this wall is the cold air return vent. This vent is rather large, I don't have the specific dimentions but it is something like 30 x 16. Seems large enough for my 1400 sq ft house. There is also a cold air return upstairs. Behind the vent is about 8" straight of duct work, then you are in the area of the furnace. The blower motor is in this section of the furnace. The blower faces the cold air return. This is all straight through and I can literally stick my arm into the blower motor if the vent cover is off (and the filter is removed).

I checked this out about a year ago, and at that time I found it to mostly be the blower making the noise. It is just the sound of air rushing. I removed the cover for the cold air return, and didn't notice much difference.

I took the blower out and cleaned it, but this didn't help. I looked around the circuit board for the blower motor, but don't see any way to slow down the blower. At least nothing that is labeled anyway.

I am trying for a cheaper solution here. My only thought right now is to line the short 8" duct with some duct insulation. Then around the area (there is a doorway next to the vent that leads outside, and a fridge right across from the vent) put some acoustic panels that may help absorb the sound.

Let me know if you need any specs like the furnace model or anything. My digital cam died so sorry, no pics. I hope someone can help quite this beast down for cheap.

|

|

| Back to top |

|

|

wendortb

Joined: 15 Nov 2006

Posts: 107

Location: Martinsville, IN

|

Link Posted: Thu Jan 03, 2008 9:14 pm Post subject: Link Posted: Thu Jan 03, 2008 9:14 pm Post subject: |

|

|

OK, I just had a thought right after posting this.

What about if I put up a sliding wall that slides from infront of the furnace closet, to the area where the cold air return and freezer are. This will still allow me to use the back door when needed, but should reflect enough of the sound away from the listening position to be bearable. I may try putting up a sheet of roofing insulation (2"thick hard foam) I got for free to see how this works. I can just lean it against the closet for a temporary solution.

My only problem with this, is that I was going to put my right surround speaker on top of the fridge. This panel will then block some of the sound of that surrond speaker. My surrounds are onix RSS300 dipole speakers.

BTW, I know the ideal way to deal with this would be to replace the blower with a quiter one, but this setup is temporary. Once I finaly build a house (in about 5 years or so) I will create my ideal room, without a furnace sitting in the room.

|

|

| Back to top |

|

|

greg_mitch

Joined: 03 May 2006

Posts: 5321

|

Link Posted: Fri Jan 04, 2008 1:33 pm Post subject: Link Posted: Fri Jan 04, 2008 1:33 pm Post subject: |

|

|

If there is space inside the mechanical closet put a botted return on the return vent with duct liner.

I am assuming right now it is just a grille in the wall and no ductwork behind it.

This will help to cut the noise.

Also if the closet doors are slatted, and the return grille is not ducted, you are pulling air from there as well. Perhaps after you duct the return you could cut some 7'x3' sections of duct liner and just tack to the inside surface of the slatted doors to kill any sound bouncing around in there.

Are the walls of the closet all the way up to the structure above? If they aren't they should be.

Maybe an actual picture would help.

|

|

| Back to top |

|

|

ecrabb

Forum Moderator

Joined: 13 Mar 2006

Posts: 15909

Location: Utah

TV/Projector: JVC RS40, Epson 5010

|

Link Posted: Fri Jan 04, 2008 4:37 pm Post subject: Link Posted: Fri Jan 04, 2008 4:37 pm Post subject: |

|

|

The foam insulation won't do anything at all. You need broadband absorption, and the foam insulation has no absorptive properties. Something with mass would provide some isolation - say, drywall for instance - but, you'd need to contain it. Since you need to allow the air to move, that won't work.

If most of the noise is coming from the return intake, you could build some sort of lined and baffled box to allow the air to flow but absorb the turbulence noise. Depending what a "box" would look like in the space, you could even destroy a piece of furniture to line with duct liner to mount against the wall. Think of something like a toy box or bench seat. Remove the bottom, line the box with duct liner, and mount to the wall high enough to provide a space at the bottom with the same cross-sectional area the original intake has. The air still moves, but a lots of the noise gets absorbed.

As for the louvered doors, that probably provides combustion air for the furnace and water heater, so you can't cover them. What you could do is put some accordion-style room dividers with absorptive material on the side facing the closet out a couple feet from the closet.

You should be able to knock those two projects out in a weekend and they should cut your noise significantly.

SC

|

|

| Back to top |

|

|

wendortb

Joined: 15 Nov 2006

Posts: 107

Location: Martinsville, IN

|

Link Posted: Fri Jan 04, 2008 5:48 pm Post subject: Link Posted: Fri Jan 04, 2008 5:48 pm Post subject: |

|

|

| greg_mitch wrote: | If there is space inside the mechanical closet put a botted return on the return vent with duct liner.

I am assuming right now it is just a grille in the wall and no ductwork behind it.

|

There is some ductwork, but it is only about 8" of duct work. I think what you are saying is for a bottled return, is something like this? This would be a side view. The gray would be a box, the black would be duct liner or something of the like. This would give me a couple of bends for the sound to get out and would be absorbed along the way. My only problem for this is I do not think I have enough room to do this.

I saw something like that this morning while searching around.

| greg_mitch wrote: |

This will help to cut the noise.

Also if the closet doors are slatted, and the return grille is not ducted, you are pulling air from there as well. Perhaps after you duct the return you could cut some 7'x3' sections of duct liner and just tack to the inside surface of the slatted doors to kill any sound bouncing around in there.

Are the walls of the closet all the way up to the structure above? If they aren't they should be.

Maybe an actual picture would help. |

It is not really pulling cold air from the closet doors. The sound from in front of the closet doors isn't too bad, but the cold air return/blower motor is terrible. I think it may be pulling air for the cumbustion part of the furnace. The water heater is electric so no worries there.

The walls are all the way to the ceiling. I will try to take a picture with my camera phone this weekend. I will also take some measurements of the cold air return.

|

|

| Back to top |

|

|

Chuck27

Joined: 09 Mar 2006

Posts: 379

Location: Caledon Township, Ontario

|

Link Posted: Fri Jan 04, 2008 5:59 pm Post subject: Link Posted: Fri Jan 04, 2008 5:59 pm Post subject: |

|

|

In my experience, the midrange and higher frequencies can be attenuated by making the the air flow turn a couple of corners. A baffle box like SC mentions would be a great place to start. High frequency sounds don't like to turn corners.

I am working on a similar problem in my own house with a furnace room next to the theatre and I'm concentrating on acoustically isolating the furnace room while still allowing enough air to get in so it doesn't starve. An oil furnace that is starved for air gets ugly very quickly.

Chuck

_________________

Chuck

using acreage for sound insulation since 1999

|

|

| Back to top |

|

|

wendortb

Joined: 15 Nov 2006

Posts: 107

Location: Martinsville, IN

|

Link Posted: Fri Jan 04, 2008 6:16 pm Post subject: Link Posted: Fri Jan 04, 2008 6:16 pm Post subject: |

|

|

| ecrabb wrote: | The foam insulation won't do anything at all. You need broadband absorption, and the foam insulation has no absorptive properties. Something with mass would provide some isolation - say, drywall for instance - but, you'd need to contain it. Since you need to allow the air to move, that won't work.

|

Actually, I was not thinking about absorbing the sound with the 2" thick foam, I was looking at deflecting it. This way the sound would bouce around the kitchen area before really getting to me. I could also make a sound absorbsion panel out of some R19 and put that on the fridge or the panel, or both. This would help absorb some of the sound. Do you think this would work?

| ecrabb wrote: |

If most of the noise is coming from the return intake, you could build some sort of lined and baffled box to allow the air to flow but absorb the turbulence noise. Depending what a "box" would look like in the space, you could even destroy a piece of furniture to line with duct liner to mount against the wall. Think of something like a toy box or bench seat. Remove the bottom, line the box with duct liner, and mount to the wall high enough to provide a space at the bottom with the same cross-sectional area the original intake has. The air still moves, but a lots of the noise gets absorbed.

|

Is that kind of like what I have posted above? Where the sound can not get directly out, but instead has to bounce around on the lined box first. I know I don't have enough room outside of the vent to put it there, because the back door to the house opens directly in front of this cold air return. The cold air return actually sucks the door against it when it is open. I really think this was a very poor design. Probably cheapest to do this way.

| ecrabb wrote: |

As for the louvered doors, that probably provides combustion air for the furnace and water heater, so you can't cover them. What you could do is put some accordion-style room dividers with absorptive material on the side facing the closet out a couple feet from the closet.

You should be able to knock those two projects out in a weekend and they should cut your noise significantly.

SC |

I think you are right, the combustion air for the furnace comes from the closet doors. The water heater is electric though.

I thought about the accordion style room divider, then I thought about just a board. I figured I could just take a sheet of plywood and hang it from the ceiling on a track, this would block the sound as well. Then I came up with the 2" foam that I have laying around and figured I could just put this on wheels instead, this would be cheaper and easier. I wonder how well the 2" foam reflects sound. Maybe I could put some sound absorbtion on the back of the foam. That way, the first layer will absorb the sound, the second layer would reflect it.

I think I may just need a "false wall" that will absorb and reflect sound, and let the furnace get it's air from the kitchen. Maybe I could make my own room divider with something like this stuff as the absorbsion, and some plywood for deflection.

The only problem I see with something that is accordian style, would be that I have to make sure that the sound does not get through the cracks where the hinges are at. I once heard that 90% of the sound gets through 10% of the area.

I know pictures would help you guys. I will take some this weekend & post them, although the photo quality will be horrible.

Thanks for the help so far.

|

|

| Back to top |

|

|

mhalsan

Joined: 09 Nov 2007

Posts: 146

Location: Astoria, Oregon

|

Link Posted: Fri Jan 04, 2008 8:47 pm Post subject: Link Posted: Fri Jan 04, 2008 8:47 pm Post subject: |

|

|

If this is a gas furnace, there might be two motors: the main fan and a smaller, high-speed combustion air blower.

The main fan can be slowed down with a fan speed control under certain circumstances, but with caution: if the temp rise through the unit gets too high, the heat exchanger's life can be shortened. In general, I wouldn't want the discharge air to exceed about 120 degrees.

The gas manifold pressure can be reduced slightly to keep the rise to a reasonable level, however this will also reduce heat output. Typical manifold pressure is 3.5" water column. I have successsfully ran the pressure as low as 2" without ignition problems.

The combustion air blower can't be altered, there's a risk of flame roll-out and/or carbon monoxide production.

I'd recommend having an HVAC tech on hand to help with this mod. Any combustion appliance can become dangerous if not set up properly.

Another option involves shutting the furnace down during a movie. Many receivers or pre/pro units have 12VDC outputs. This output could operate a small relay with a normally-closed contact, which would interrupt the thermostat conductor tied to the "W" terminal on the furnace. When the relay energizes, the contact opens, and the call for heat would be removed. The 12V output on the receiver could be programmed in a number of ways, probably a softkey on a programmable remote would be the most useful. The furnace would operate normally when the receiver is turned off. This method would not involve any mods to the furnace.

Thanks, Mark

_________________

Sigh. We are getting aggravated (yes, we are....)

|

|

| Back to top |

|

|

wendortb

Joined: 15 Nov 2006

Posts: 107

Location: Martinsville, IN

|

Link Posted: Fri Jan 04, 2008 9:37 pm Post subject: Link Posted: Fri Jan 04, 2008 9:37 pm Post subject: |

|

|

| mhalsan wrote: | If this is a gas furnace, there might be two motors: the main fan and a smaller, high-speed combustion air blower.

The main fan can be slowed down with a fan speed control under certain circumstances, but with caution: if the temp rise through the unit gets too high, the heat exchanger's life can be shortened. In general, I wouldn't want the discharge air to exceed about 120 degrees.

The gas manifold pressure can be reduced slightly to keep the rise to a reasonable level, however this will also reduce heat output. Typical manifold pressure is 3.5" water column. I have successsfully ran the pressure as low as 2" without ignition problems.

The combustion air blower can't be altered, there's a risk of flame roll-out and/or carbon monoxide production.

I'd recommend having an HVAC tech on hand to help with this mod. Any combustion appliance can become dangerous if not set up properly.

Another option involves shutting the furnace down during a movie. Many receivers or pre/pro units have 12VDC outputs. This output could operate a small relay with a normally-closed contact, which would interrupt the thermostat conductor tied to the "W" terminal on the furnace. When the relay energizes, the contact opens, and the call for heat would be removed. The 12V output on the receiver could be programmed in a number of ways, probably a softkey on a programmable remote would be the most useful. The furnace would operate normally when the receiver is turned off. This method would not involve any mods to the furnace.

Thanks, Mark |

I read that twice, and now I think I understand your point.

I can change my main fan, but this may change the temp of the combustion discharge air. To change the temp of the discharge air, I would have to change the manifold pressure. If the manifold pressure is set incorrectly, I could die. To sum that up, call a HVAC specialist before changing the fan speed (or can I check the temp of the discharge air myself?).

I thought about shutting down the furnace during a movie. Between the projector and all the other electronics, heat shouldn't be too much of a problem. I didn't even think about tying in to a relay, but I don't think that is necessary for my setup. I can just manually turn down the thermostat when I don't want the furnace to come on. It is all in the same room so it isn't much of a hassle. Thanks for the idea though.

I am thinking a combination of these is going to be my best bet. If I don't want any sound, I can just turn the furnace off. I will look at doing something with the duct to add corners, but I don't know that there is enough room to do this. I need a lot of sq ft for the duct, and I don't have much depth to work with. I will try some sound absorbtion panels on the fridge and around the air intake. I was planning on building some anyway in a month. I will just try them in different places and see what levels I get. I will also try the 2" foam to see if it deflects any sound from the seating position. I can do this over the weekend.

Thanks for all the replies guys, I really appreciate it.

|

|

| Back to top |

|

|

wendortb

Joined: 15 Nov 2006

Posts: 107

Location: Martinsville, IN

|

Link Posted: Sat Jan 05, 2008 12:25 am Post subject: Link Posted: Sat Jan 05, 2008 12:25 am Post subject: |

|

|

ok, got some measurements & such. The duct work, from the outside of the drywall to the actual furnace is 10" deep. The opening in the drywall where the cover is 27.75"x13.75". The opening on the furnace is 23"x14.5". Just in front of the cold air return, I am registering 78db. In front of the closet doors I get 72db. I didn't think that much sound came out of the closet doors, but I guess so.

Here you can see where the closet, door, and fridge are located. At the bottom of the closet there on the side is the cold air register.

Here is a pic of the ductwork of the cold air return. At the back of there is my furnace filter.

I am going to try the 2" foam infront of the area and see why my spl meter reads.

|

|

| Back to top |

|

|

greg_mitch

Joined: 03 May 2006

Posts: 5321

|

Link Posted: Sat Jan 05, 2008 5:56 pm Post subject: Link Posted: Sat Jan 05, 2008 5:56 pm Post subject: |

|

|

Holy cow you don't have any room there.

I was actually saying booted return, not bottled return. I can't type. It is a baffle box like SC mentioned as well.

You don't have a lot of room there though.

Does the sound of the cold air return greatly reduce when the grille is removed? Maybe the return grille is undersized?

Perhaps you can make it larger so there isn't such a large pressure drop across it? Or change grille types, something with a larger free area. Like an eggcrate type? Do you by chance know how much CFM is going through the grille? Maybe some info on the furnace blower would clue you in.

If you give me the CFM I could maybe look up a grille with better sound characteristics?

JUst a thought.

|

|

| Back to top |

|

|

AnalogRocks

Forum Moderator

Joined: 08 Mar 2006

Posts: 26690

Location: Toronto, Ontario, Canada

TV/Projector: Sony 1252Q, AMPRO 4000G

|

Link Posted: Sat Jan 05, 2008 10:14 pm Post subject: Link Posted: Sat Jan 05, 2008 10:14 pm Post subject: |

|

|

Why not try two pannels that extend 2/3rd's of the way across your cold air return? Put one at the front and one a couple of inches away from the filter. Just for testing. Maybe wrap them in foam and see if that quiets anything down.

It's like the baffling in a car muffler, you don't want to ubstruct the air flow too much but you need to break up the sound waves.

Oh and just for safety, take a piece of the foam you want to use, outside, and do a fire check on it. You may find it goes up with a 'Wooooofff'. Some foams do that and other's burn more slowly. Could be the difference between getting out in a fire and not.

_________________

Tech support for nothing

CRT.

HD done right!

|

|

| Back to top |

|

|

wendortb

Joined: 15 Nov 2006

Posts: 107

Location: Martinsville, IN

|

Link Posted: Sun Jan 06, 2008 2:15 am Post subject: Link Posted: Sun Jan 06, 2008 2:15 am Post subject: |

|

|

greg_mitch: I know I don't have any room, that is why I was looking at sound deflection and absorbtion. I checked the spl of the cold air return with the grill on and off. With the grill on it is actually 1 db quieter 2 foot from the cold air return. Because of this, I don't think it is undersized. I will try to find the model number tomorrow and get it to you.

AnalogRocks: I will try the foam idea. Good point with the foam. I think for the permanent installation, I will probably go with something that is rigid fiberglass. That way I am sure it doesn't burn and it is rigid enough to stand on it's own. It will also absorb some sound too. Maybe a ceiling tile or something. I don't know, I will have to do more research as to what they use in the HVAC ducts. Would definitely suck if a fire broke out.

I really appreciate the help. I will try to find the furnace model info.

|

|

| Back to top |

|

|

wendortb

Joined: 15 Nov 2006

Posts: 107

Location: Martinsville, IN

|

Link Posted: Sun Jan 06, 2008 4:51 pm Post subject: Link Posted: Sun Jan 06, 2008 4:51 pm Post subject: |

|

|

I got the following information off the blower, I also saw the same model number listed on a sicker on the furnace, I didn't see any other info on the furnace for a model number. I listed the numbers that were listed for lp, since that is what I have.

Goodman Manufacturing Company L.P.

GMP125-4

Cat. 1

Heating Input (Btu/Hr) 100,000

Output Capacity (But/Hr) 80,000

Tempurature Rise of F 45-75

Manifold Pressure (In W.C.) 10

External Static Pressure (in W.C.) .20

Motor 1/2 hp

Blower (in) 10x10

Aux Limit Set (F) 135

Max Gas Supply to furnace (in W.C.) 14

Certified 1993

I am sure you didn't need all that info, and there is probably something you need that I didn't write down. But that is what looked interesting to me.

I searched around the internet a little, and I think I did find where they sell a replacement circuit board. Can anyone look at this and tell me how you set the fan speed differently on this board? I would like to look to see what speed mine is set at for starters, just don't know where to look. I am guessing it is just where the wire is hooked up on there that tells the fan what speed to run at.[url=http://climatedoctors.zoovy.com/product/ICM24/ICM280_Goodman_Furnace_Control_Circuit_Board.htmlLinky[/url]

I think I also might have found some type of manual or something, but I don't see the specs for LP listed there.

|

|

| Back to top |

|

|

Brian Hampton

Joined: 22 Apr 2006

Posts: 1174

|

Link Posted: Sun Apr 27, 2008 4:23 pm Post subject: Link Posted: Sun Apr 27, 2008 4:23 pm Post subject: |

|

|

Hey,

Maybe not useful but thought I should mention.... Maybe something about the heating system is loose and therefore vibrating more then it should and making it louder.

I became a home owner a few years back and our heating system (oil boiler) would wake me up in the night even though it was in the basement and I was in the second floor. There's lots of panels and covers and stuff on the system and I noticed by putting pressure on some of these by hand when it was ruinning the system got much quieter. I then re-seated or tightened down a few things and it was much quieter.

-Brian

EDIT- Now that I think about the "blower" part a bit... That blower motor may have bushings to mount which need to be replaced or serviced or maybe it could be time for a new one.

|

|

| Back to top |

|

|

paw

Joined: 08 Mar 2006

Posts: 1176

Location: Arvada, CO

|

Link Posted: Tue Apr 29, 2008 3:24 am Post subject: Link Posted: Tue Apr 29, 2008 3:24 am Post subject: |

|

|

I'd just turn off the furnace. There's no room to modify the return. Though if you wake up cold, don't blame us.

If you want to be more sophistcated, use Mark's (mhalsan) relay idea.

_________________

Aubrey

|

|

| Back to top |

|

|

ronronzz

Joined: 28 Apr 2009

Posts: 1

|

Link Posted: Tue Apr 28, 2009 3:54 pm Post subject: Link Posted: Tue Apr 28, 2009 3:54 pm Post subject: |

|

|

| wendortb wrote: | ok, got some measurements & such. The duct work, from the outside of the drywall to the actual furnace is 10" deep. The opening in the drywall where the cover is 27.75"x13.75". The opening on the furnace is 23"x14.5". Just in front of the cold air return, I am registering 78db. In front of the closet doors I get 72db. I didn't think that much sound came out of the closet doors, but I guess so.

Here you can see where the closet, door, and fridge are located. At the bottom of the closet there on the side is the cold air register.

Here is a pic of the ductwork of the cold air return. At the back of there is my furnace filter.

I am going to try the 2" foam infront of the area and see why my spl meter reads. |

its actually fits about what you installed Furnace Filter, good

_________________

Furnace Filter

|

|

| Back to top |

|

|

loribates

Joined: 02 Dec 2007

Posts: 185

Location: KS

|

Link Posted: Wed Apr 29, 2009 3:29 am Post subject: Link Posted: Wed Apr 29, 2009 3:29 am Post subject: |

|

|

Wow.... I love my boiler.

Aside from the fact I still get heat gain of about 5 degrees even after the boiler shuts off (BONUS!!). Nothing but a whoosh when it lights and a little whirring of the water through the radiators. I only hear it late at night when I'm falling asleep. I have the same trouble as you though because I do have a central AC in the basement so during the summer when that's running it can really peeve you off during a movie. I just shut it off. If and when you find a solution I'm looking forward to seeing what you come up with.

_________________

Lori Bates

|

|

| Back to top |

|

|

AnalogRocks

Forum Moderator

Joined: 08 Mar 2006

Posts: 26690

Location: Toronto, Ontario, Canada

TV/Projector: Sony 1252Q, AMPRO 4000G

|

Link Posted: Wed Apr 29, 2009 5:19 am Post subject: Link Posted: Wed Apr 29, 2009 5:19 am Post subject: |

|

|

Neat! This thread was resurected 365 days later.

_________________

Tech support for nothing

CRT.

HD done right!

|

|

| Back to top |

|

|

jkruger

Joined: 24 Oct 2007

Posts: 2435

Location: Carlsbad, CA

|

Link Posted: Wed Apr 29, 2009 2:19 pm Post subject: Link Posted: Wed Apr 29, 2009 2:19 pm Post subject: |

|

|

| AnalogRocks wrote: | | Neat! This thread was resurected 365 days later. |

Wasn't 2008 a leap year? Oh yeah Feb 29th came before this post date.

|

|

| Back to top |

|

|

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Forum powered by phpBB © phpBB Group

|

|